Gruppo Veronesi consolidates its leadership of the Italian agrifood sector with 2018 sales close to €3 billion

The company is maintaining sustainable growth by continuing to invest in its high-tech Italian factories....

Read all

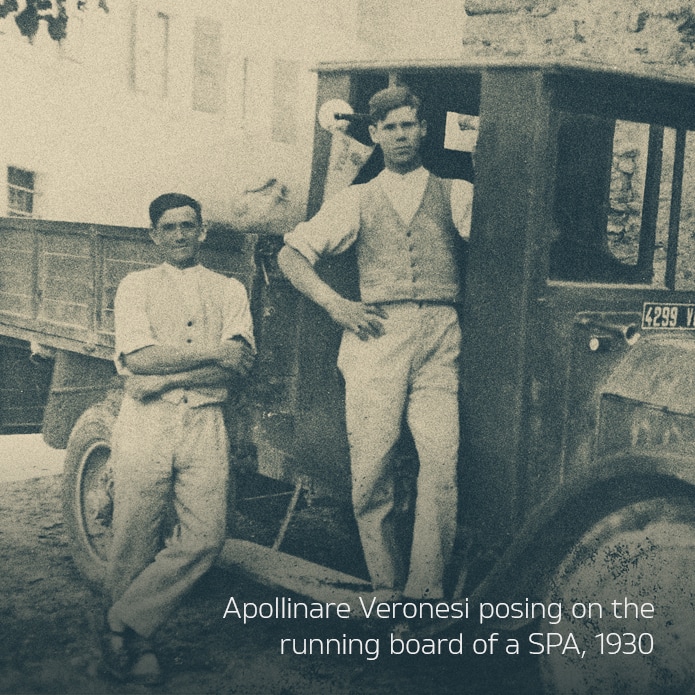

A life spanning the 20th century that left a profound impression on Italian life and culture.

People, projects, initiatives – there are many ways of experiencing Gruppo Veronesi’s values, and each has its own story to tell.